Laser Cutting

Leverage our Experience

Our factory in China provide a complete sheet metal prototype solution via flexible material, surface finish options and strong manufacturing capacity for both small and large quantity projects

Engineering Support

We service 7*24hr online engineering support for your custom sheet metal engineering and manufacturing questions. It includes case-by-case suggestions to help you to save cost earlier at the beginning of the design process and continuous improvement for more benefits

Assured High Quality

As an ISO 9001:2015 certificated sheet metal manufacturing factory, we provide material and full dimensional inspection reports according to your request. You can always be confident with the parts you get from FCE will exceed your expectations

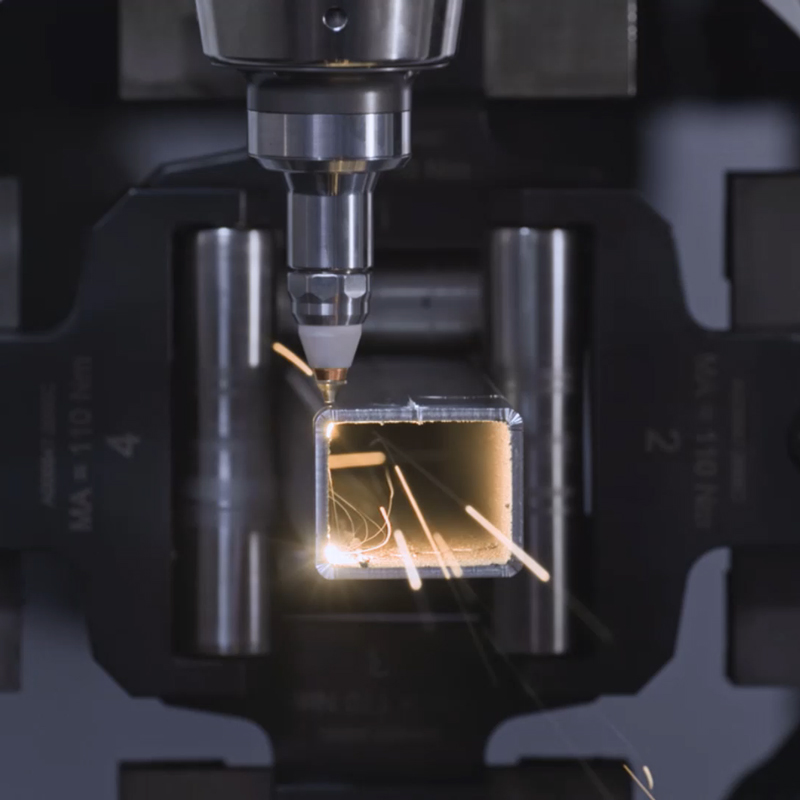

What is laser cutting?

Laser cutting is a thermal cutting process that uses high-power laser to cut metals and achieve high-quality prototype sheet metal parts. Applicable for all industries.

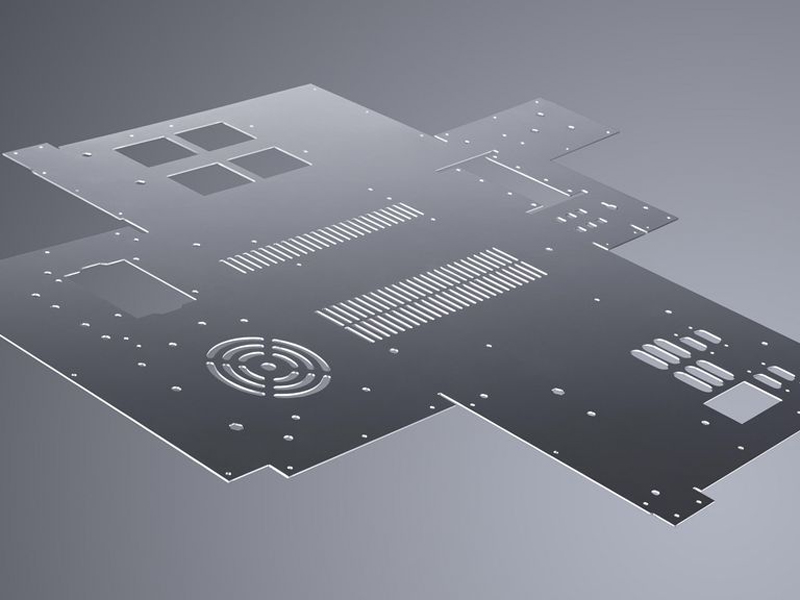

Capability

Cutting area: Up to 4000 x 6000 mm

Material thickness: Up to 50 mm

Laser sources: Up to 6 kW

Repeatability: Ps: +/- 0.05 mm

Position accuracy: Pa: +/- 0.1 mm

Laser cutting advantage

• Top cutting precision and positional accuracy

• improved edge quality and surface finish

• strong repeatability

• the use of materials not cut by traditional devices

• drilling and engraving in addition to cutting

• negligible workpiece degradation

• cost-effectiveness

• minimal thermal stress zone

• cuts of complex shapes

Laser cutting material types

Aluminum

High strength-to-weight ratio\ Aerospace components

Copper

>99.3% Purity + Superior electrical conductivity

Stainless steel

Good corrosion resistance + High Hardness

Steel

Good machinability + Excellent electrical conductivity